I NOSTRI SOFTWARE

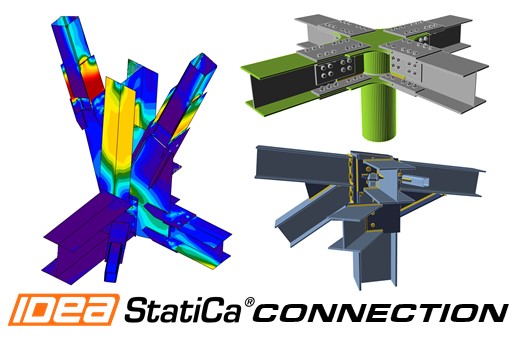

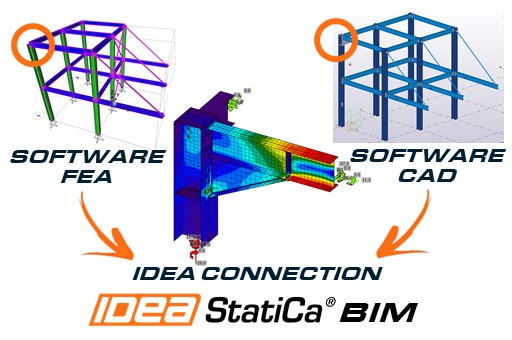

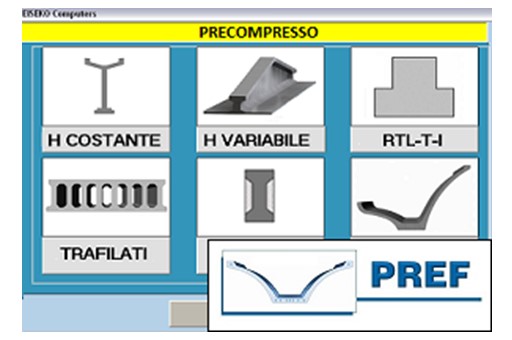

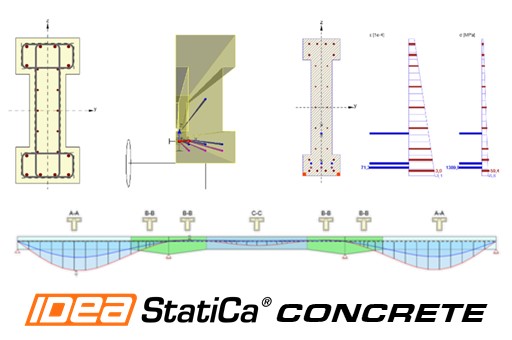

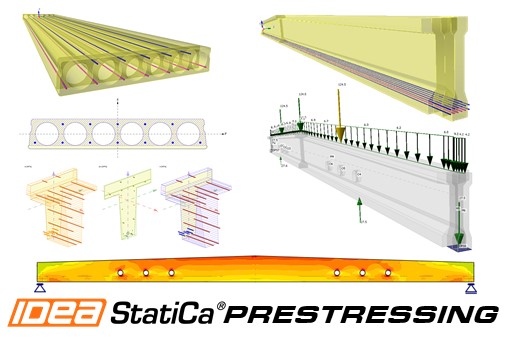

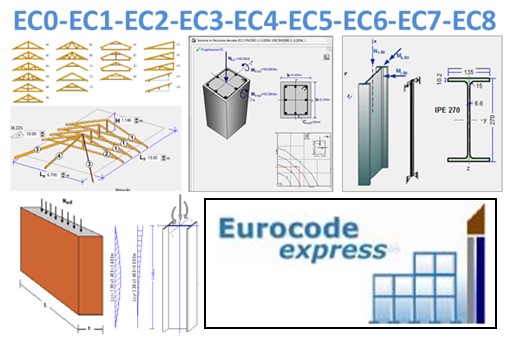

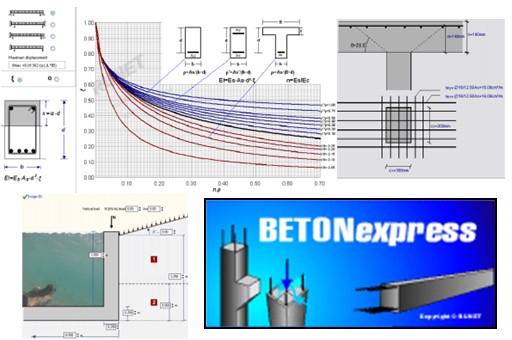

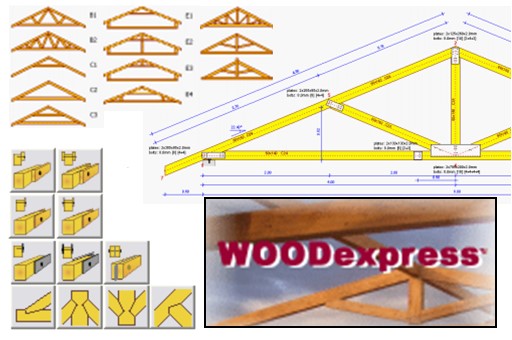

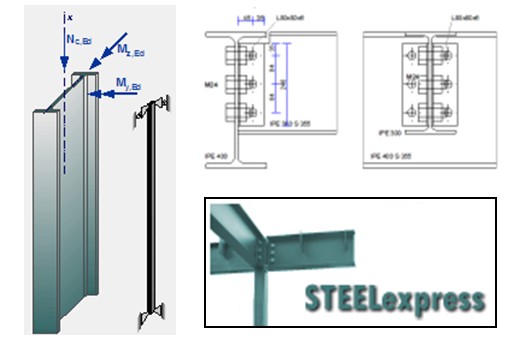

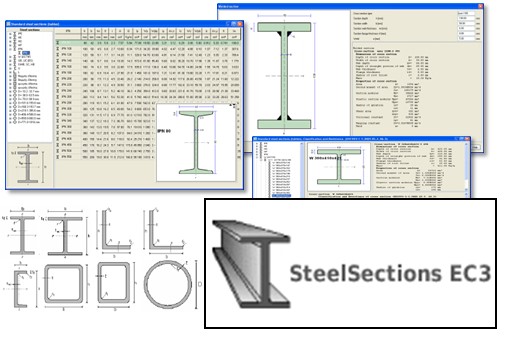

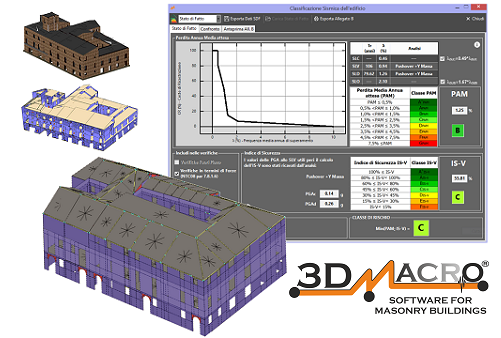

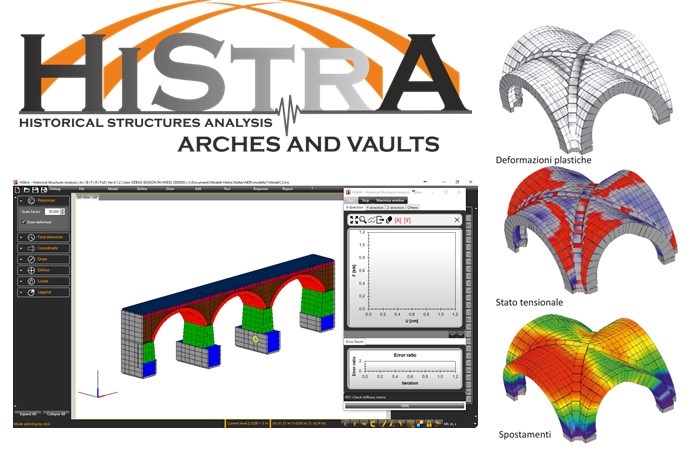

EISEKO COMPUTERS sviluppa e ridistribuisce software di calcolo e disegno per il progetto, la verifica e la preventivazione di strutture prefabbricate, elementi precompressi, strutture in legno, strutture in cemento armato e strutture in acciaio; software per le connessioni in acciaio; software per l'analisi strutturale degli edifici, software CAD ZWCAD per il disegno tecnico, software per l'analisi geotecnica.

Richiesta informazioni

Compila il modulo sottostante ed inviaci la tua richiesta, il nostro staff risponderà nel minor tempo possibile all'indirizzo email inserito.

News, eventi e promozioni

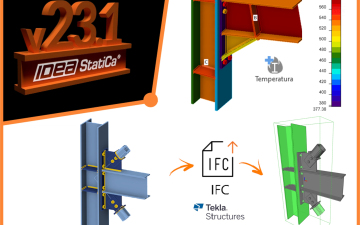

IDEA STATICA - RILASCIATA LA NUOVA VERSIONE 23.1

Rilasciata la nuova versione IDEA StatiCa 23.1 ►►►Leggi le Release…

GEOFLUID 2023 | 13-16 SETTEMBRE - PIACENZA

Saremo presenti al GEOFLUID 2023 di PIACENZA dal 13 al 16 Settembre. Padiglione 1 - Corsia A - STAND 41 Geofluid è la più…

GEO5 2023 - Nuovo Aggiornamento

App Mobile per Data Collector GEO5 Data Collector - Applicazione per dispositivi mobile (iOS, Android) per la raccolta dei dati durante…

FIERA SED | CASERTA | 11 -13 Maggio 2023

Saremo presenti al SED 2023 che si terrà a CASERTA dall'11 al 13 Maggio. Eiseko ti permetterà di partecipare a…

CYPE Architecture: Software Bim gratuito

CYPE Architecture: Software Bim gratuito